Luxembourg-based R3 Robotics (formerly Circi Li-ion) has raised €20m in funding to expand from upcycling batteries to fully dismantling electric vehicles (EV) in a bid to solve Europe’s supply of critical raw materials.

Europe depends heavily on foreign supply chains for the majority of its critical minerals — key components found inside everyday consumer electronics and systems central to decarbonisation such as electric vehicle batteries — with recent geopolitical tensions putting that dependency under the spotlight.

The EU’s Critical Raw Materials Act, which aims to ensure a secure, sustainable supply of critical minerals on the continent, underscores the need to shore up domestic supply. The bloc’s Battery Regulation also has a 70% recycling target for lithium-based batteries by 2030, alongside material recovery and recycled content requirements.

The opportunity behind that is core to R3’s expansion. “We started off with batteries because they had clear unit economics for what we’re doing,” Antoine Welter, R3’s cofounder and CEO tells Sifted.

“As tech has matured the amount of products you can dismantle in an ecologically viable way has expanded, and we want to follow that trend,” he says. The company aims to secure the supply chain of materials in Europe without “having to depend on more risky geographies.”

How it works

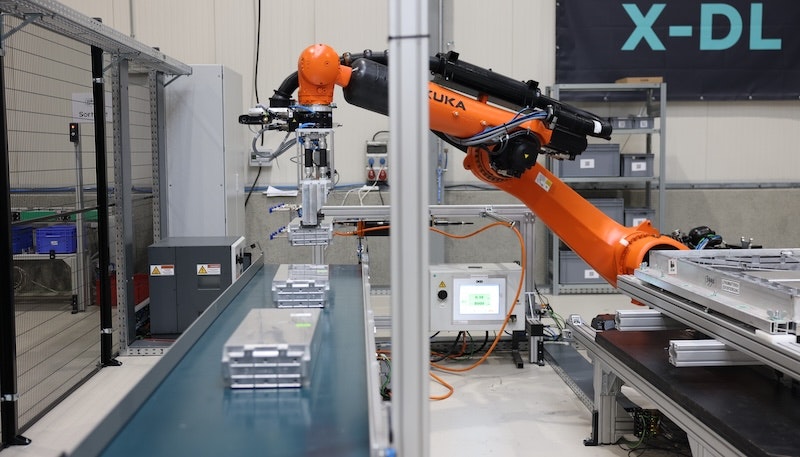

R3’s platform uses a combination of computer vision, AI and robotic tooling to automate the disassembly of lithium-ion battery packs, e-motors, power electronics and other high-value electrified components.

Welter says R3 buys 85% of its hardware off the shelf, to which it attaches end effectors, the robot equivalent of a hand, which are designed in-house. It has also built the software stack.

“It’s a bit like prompting ChatGPT to dismantle an object in different steps,” he says. “The system does what a human would do if they were dismantling something.”

R3 Robotics’s process capacity at its German site in Karlsruhe is 1,500 tonnes of batteries per year; it also has an R&D and pilot facility in Luxembourg. Both either repairs the products it dismantles for reuse or for clean recycling streams.

The company makes money in a few ways, charging a fee for dismantling batteries that it collects from customers, as well as selling on components it has repaired.

It also sells its dismantling system using a robots-as-a-service model, charging a subscription fee to clients who install on their own sites. In such cases the clients own the materials they recover. R3 Robotics is scaling this aspect of its model this year.

“The unit economics work best when you minimise logistics,” he says. “You need to treat the product as close as possible to where it’s sourced, so we’re not looking into opening loads of our own facilities.”

How R3 Robotics will spend its fresh capital

The €14m Series A was co-led by HG Ventures and Suma Capital, with participation from Oetker Collection, the European Innovation Council Fund (EIC Fund), and existing shareholders including BonVenture, FlixFounders, and EIT Urban Mobility. The round also included €6m in European grants.

The company wants to use some of the money to expand its disassembly facility in Karlsruhe, which is already operating as a fully certified, industrial-scale reference site.

It also wants to expand its team across engineering, AI, software and operations, as well as finance its go-to-market strategy into new geographies. France and Germany are key markets, and Welter says expansion into the US is on its roadmap for this year.