With the growth of the secondary battery industry, each manufacturer is accelerating the expansion of production plants. In this process, securing yield is cited as a core challenge that determines the competitiveness of manufacturers. A single small defect can directly lead to production disruptions, significant cost losses, and a decline in corporate credibility. In particular, if minute issues that occur in the slurry (active material mixture) process, which sits at the very front end of secondary battery electrode manufacturing, are not detected in time, they cause product defects, making stricter verification essential. Nevertheless, the industry currently diagnoses the opaque slurry surface mainly through visual inspection and operator experience. A startup has emerged aiming to solve this problem with technology. ThruSight, which is developing equipment that can “see through” the interior of electrode slurry using impedance tomography, is taking on this challenge. CEO Kim Kwang-tae, who majored in robotics and worked as a researcher at a secondary battery manufacturing startup, is leading the technology development.

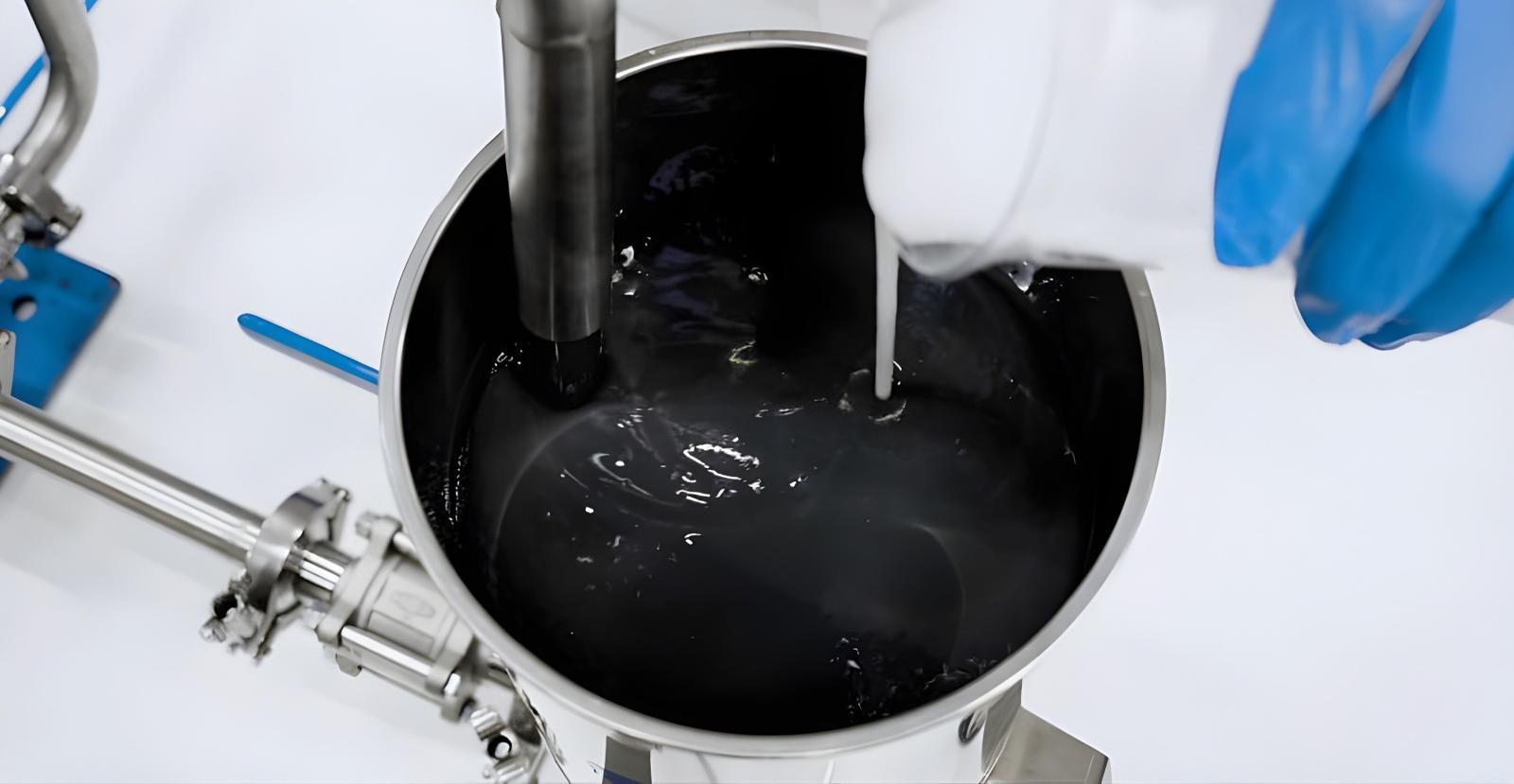

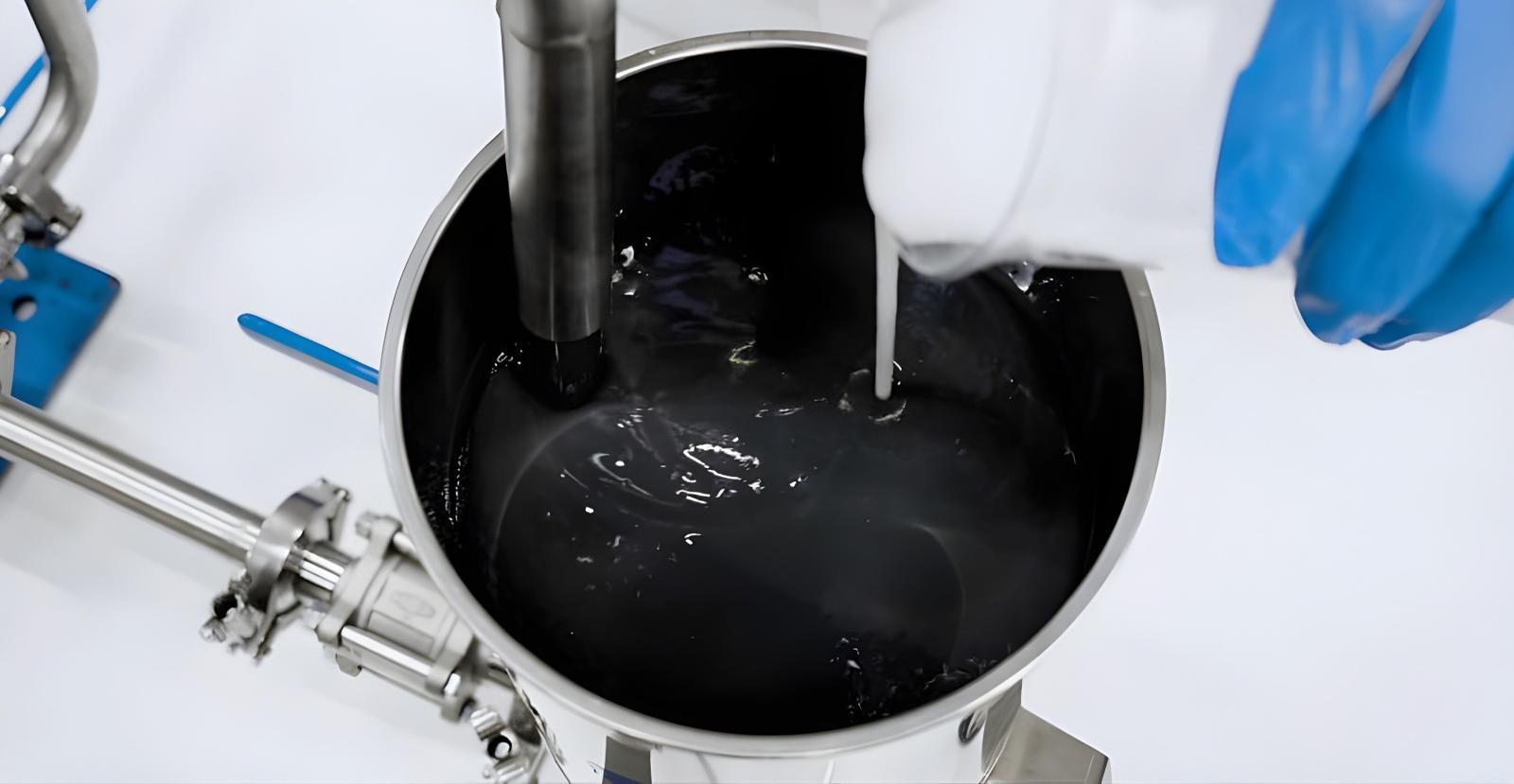

Secondary battery electrode slurry process / Source = Silverson website

Diagnosis of secondary battery electrode slurry processes still reliant on “gut feeling”… the starting point of the startup

Secondary battery electrode slurry is an opaque material, making it difficult to identify internal defects by observing only the surface. Until now, there have been many cases where workers visually judged whether the mixture state was uniform or whether bubbles were present. This posed a major risk that could cause yield deterioration, process delays, and product defects.

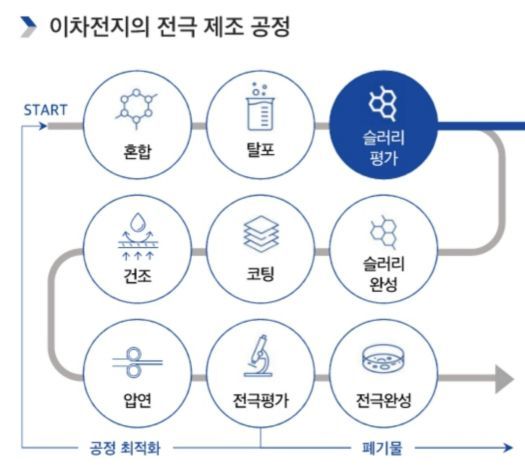

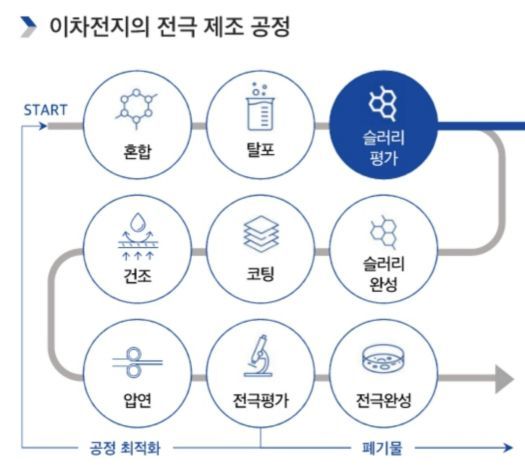

Secondary battery electrode manufacturing process / Source = ThruSight

CEO Kim Kwang-tae said, “Secondary batteries are a culmination of cutting-edge processes, yet the actual process of determining defects still relies heavily on the human eye and senses. While working as a researcher at a secondary battery startup, I experienced electrode manufacturing, performance evaluation, and equipment development, and clearly recognized this issue. At the time, even officials at large battery manufacturers asked whether there was a breakthrough method to view slurry cross-sections, which convinced me this was an area in need of improvement and led me to start this business,” adding, “I judged that nearly half of electrode defects originate in the slurry. If the root causes of defects can be identified early and corrected at the front end of the process, product scrappage and rework can be significantly reduced. Therefore, I researched and explored various methods to find a technology to measure slurry defects.”

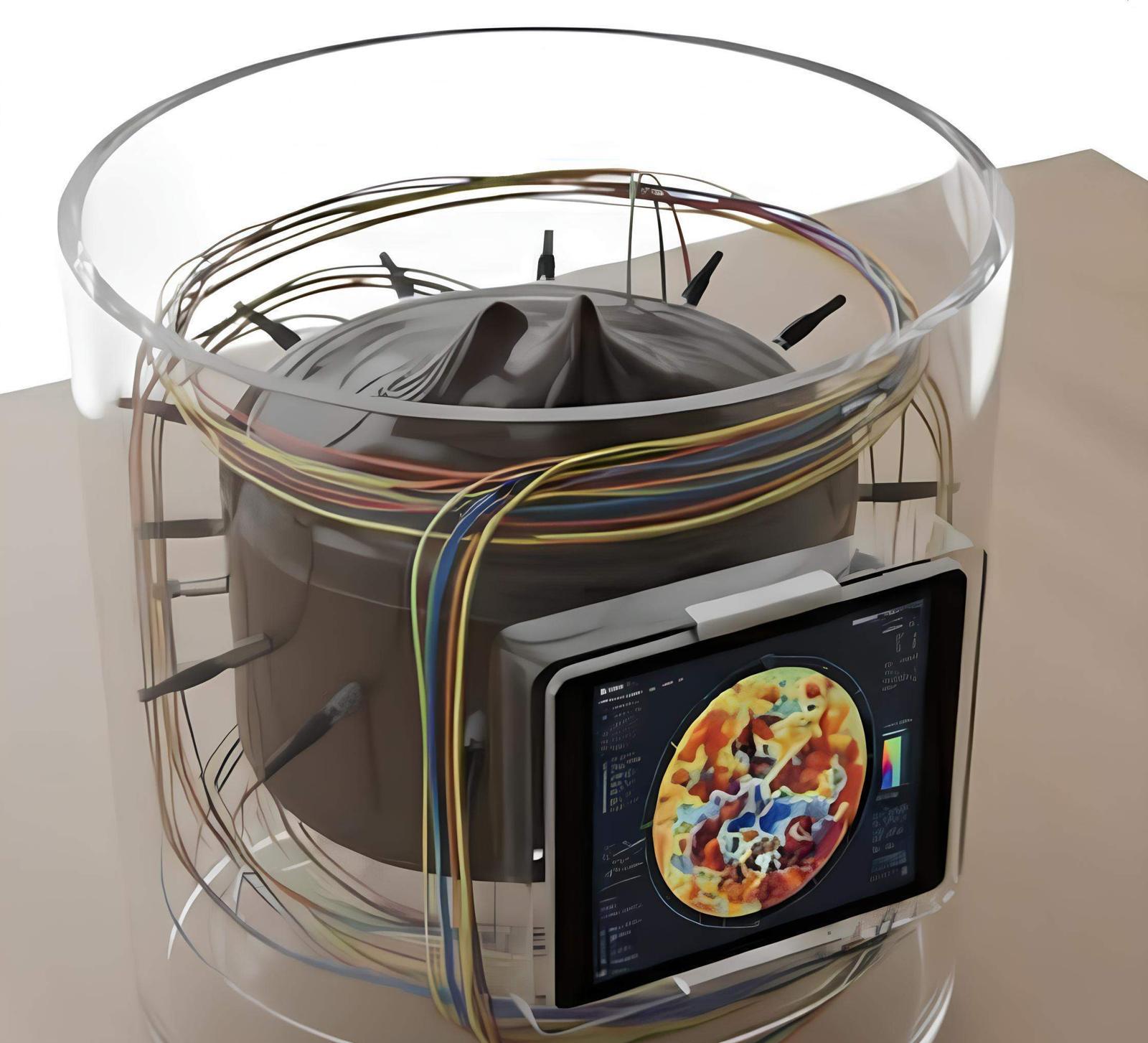

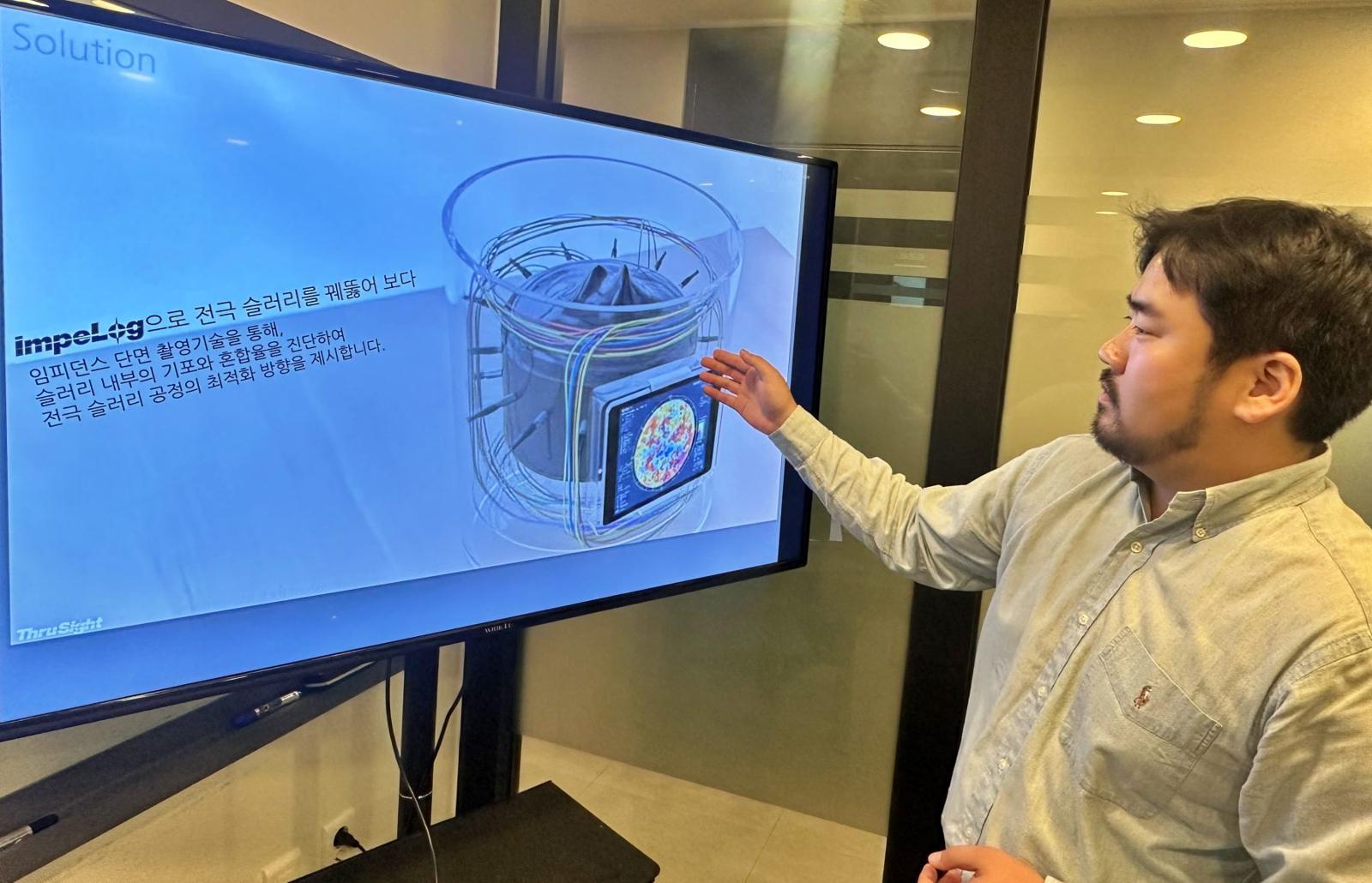

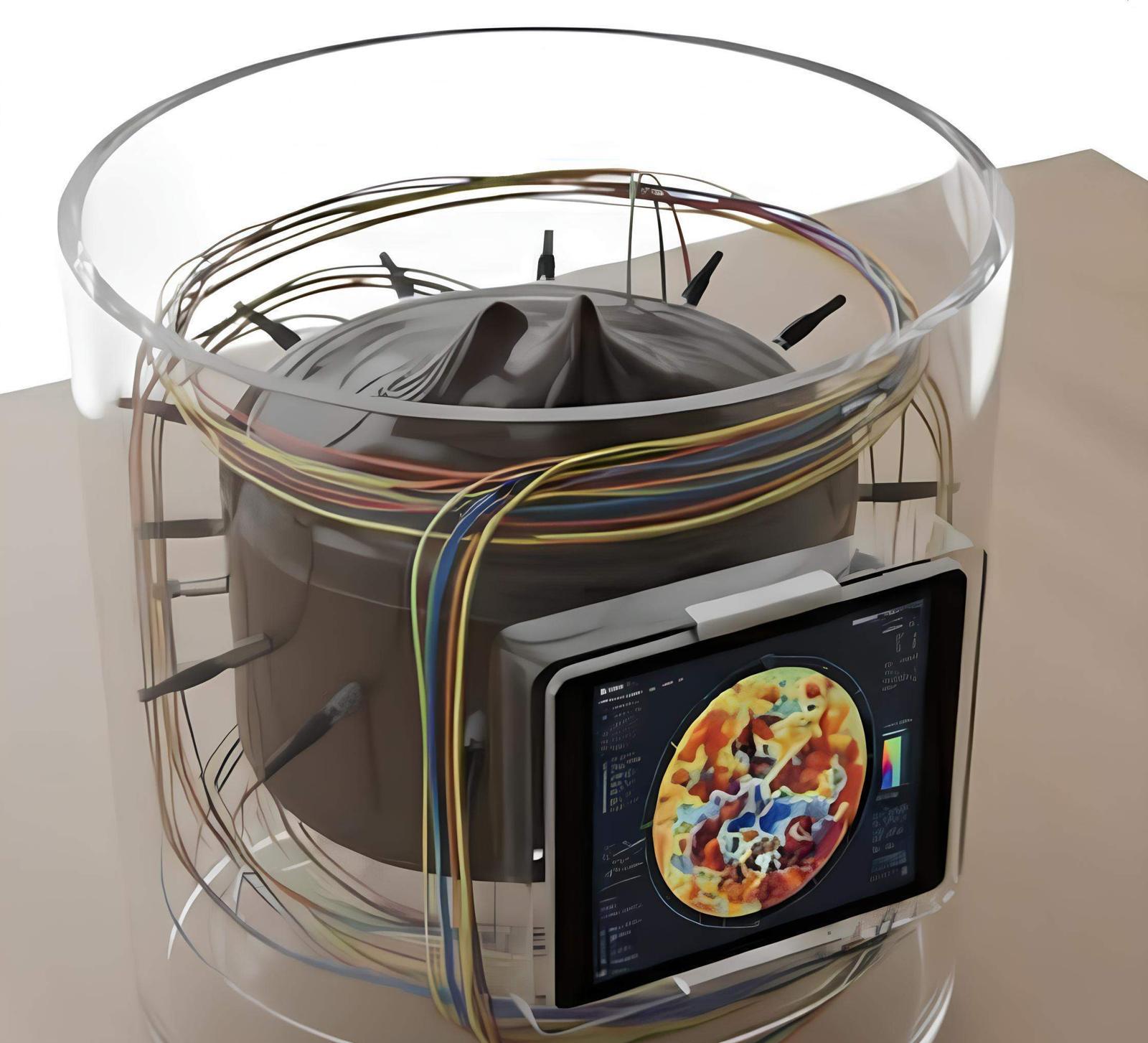

He continued, “Initially, I tried applying X-ray imaging, but the energy was too strong to capture slurry cross-sections. Ultrasonography also had limitations in use because it requires heterogeneous materials for reflection. After repeated trial and error, I found impedance tomography technology, which had been used for medical lung cross-sectional imaging,” and went on, “Using this technology, we are developing IMPELOG, equipment to detect defects in secondary battery slurry. IMPELOG operates by applying current to the slurry from 360 degrees, measuring voltage changes that appear at each segment as the current spreads, and then back-calculating these to reconstruct a cross-sectional image. We plan to apply AI-based analysis methods and optimization processes tailored to the characteristics of cathode and anode slurries. In this process, we aim to introduce differentiated functions not previously available, such as identifying reusable slurry, and are conducting R&D with that goal in mind.”

IMPELOG concept under development by ThruSight / Source = ThruSight

He added, “As a result of simulations applying IMPELOG to the electrode slurry process, we found that final yield could be raised from 64.8% to 74.9%. This corresponds to an annual cost reduction of about KRW 1.2 billion per plant,” and said, “In order for the market and investors to gain confidence, we must prove effectiveness by applying the solution to actual slurry, so we are accelerating the development of our MVP (Minimum Viable Product). With support from the Preliminary Startup Package operated by SeoulTech, we are producing the MVP and currently correcting algorithm errors and optimizing circuits. Once the MVP is completed, we will also conduct a PoC (Proof of Concept) with SeoulTech. The PoC will proceed by receiving actual cathode and anode slurries for batteries, attempting cross-sectional imaging, and verifying whether IMPELOG can be used in industrial field environments.”

CEO Kim Kwang-tae explaining the principles of IMPELOG / Source = ITDonga

Collaboration with SeoulTech as a turning point for growth… “Will grow from equipment to a data platform company”

CEO Kim Kwang-tae stated that he received significant support in technology development and commercialization after being selected for the SeoulTech Preliminary Startup Package.

He said, “With the help of the SeoulTech Startup Support Group, we not only produced the MVP but also gained various insights. In particular, by taking part in a one-night, two-day networking event among startups, we exchanged a wide range of ideas with other innovators. For example, through in-depth conversations with a professor-founder researching semiconductors, we confirmed the potential to extend the application of IMPELOG equipment to the nano particle measurement market,” adding, “In addition, with support from SeoulTech, we gained a variety of opportunities in areas such as investment strategy, building a patent portfolio, and discovering partner companies for equipment production.”

Lastly, he outlined ThruSight’s future plans.

CEO Kim Kwang-tae said, “Seeing is believing, so we are staking everything on the launch of the MVP so that we can present the idea as a tangible product. In the battery industry, we want to be evaluated as having fundamentally changed the approach to diagnosing secondary battery electrode slurry before and after the release of IMPELOG,” and continued, “We have also set a mid- to long-term roadmap for the company. We plan to launch and advance the 2D cross-sectional imaging IMPELOG MVP and complete PoC with SeoulTech by next year. By 2027, we will integrate high-resolution versions and AI-based anomaly detection algorithms into the equipment. By 2028, we plan to apply 3D imaging to IMPELOG and advance it further, and after 2028, we will expand collaboration with battery manufacturers and equipment companies and enter the global market.”

Kim Kwang-tae, CEO of ThruSight / Source = ITDonga

He went on, “ThruSight is not simply an equipment sales company; ultimately, it seeks to grow into a company that provides a quantitative data-based collaboration infrastructure among battery manufacturers, materials companies, and equipment companies,” and added, “Just as Apple sells innovation rather than iPhones, and Amazon sells convenience rather than products, ThruSight aims to sell technology that turns doubt into certainty. With technology that can see through the inside of secondary battery electrode slurry, we will do our utmost to maximize productivity amid the yield competition facing the industry.”

ITDonga reporter Kim Dong-jin ([email protected])

ⓒ dongA.com. All rights reserved. Reproduction, redistribution, or use for AI training prohibited.

Source link